Milling & Mashing

Milling

Once the barley has been dried, a malt mill crushes the barley with rollers to produce a coarse grist which is then sent to the mash tun and mixed with hot water. The barley is crushed to maximise the amount of sugar that can be extracted during mashing, the next stage on this complex journey of making whisky.

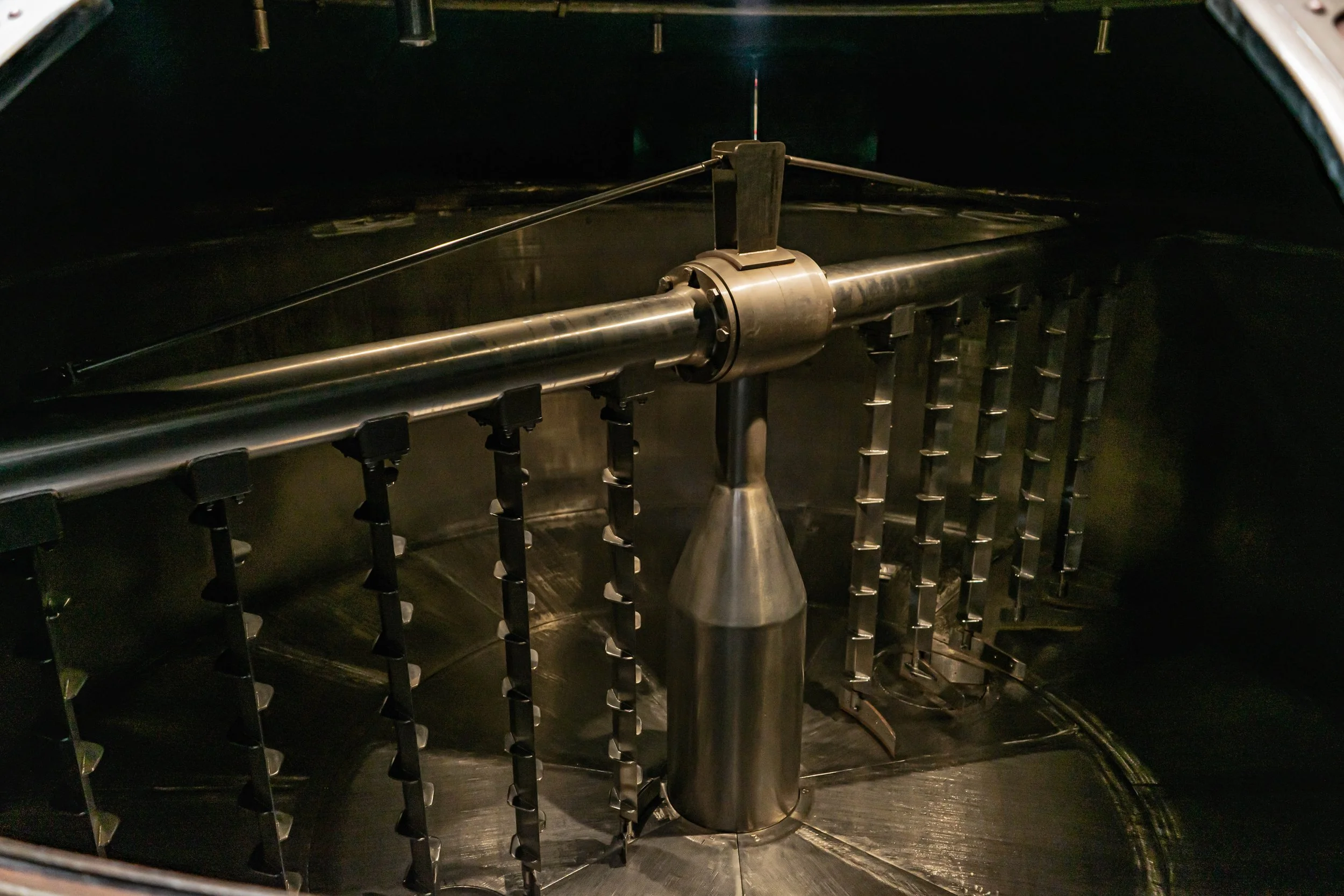

The Porteus Malt Mill from the Tobermory Distillery

If you are able to visit a distillery, look to see whether it is an original Porteus Malt Mill. Some of these are more than 100 years old and are still working away These malt mills were so well manufactured they never needed replacement or repair. Perhaps predictably, the company eventually went out of business and had to close its doors in 1974!

Mashing

The malting process led to the barley grain producing diastase enzymes, including amylase. These enzymes are crucial to the whole process as they catalyse the breakdown of the starches in the barley into maltose, a type of sugar that will feed the yeast as it produces alcohol during fermentation.

A Mash Tun at Glengoyne Distillery

As enzymes are responsive to heat, the crushed malted barley grist is mixed with hot water in the mash tun and gently agitated. After perhaps an hour, a sugar-rich solution , the wort, is drained off, and a second batch of slightly warmer water is then added to the mash tun to tease out more of the sugar. Further, and hotter waters may be used to create the ‘sparge’ which is then kept to be used as the first water for the next mash. In most distilleries, the mash tun is run electronically, as at Glengoyne (pictured). Glenturret is the last distillery in Scotlad that still has a manually operated mash tun.

Once the wort has been extracted for fermentation, what’s left—the draff—has traditionally been sent to local farmers to feed their cattle, although some large distilleries now dry the draff and burn it a a renewable source of energy.

Explore fermentation in the next article of our Exploring Whisky blog series.